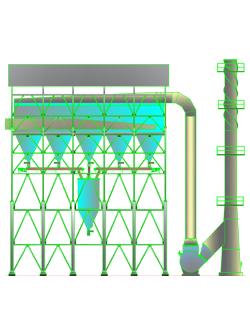

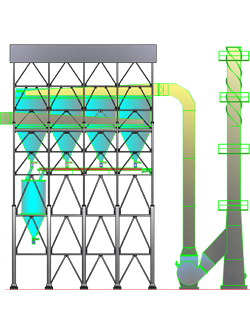

Large size Bag Houses handling larger volumes, say more than 50,000 m3/Hr (~ 500m2 filter area), Bag Filters are manufactured & supplied with pre-fabricated panels / modules, easy to assemble at site. Pre-fabricated modules are sized considering shifting / transportation limitations. Sub-assemblies are manufactured for bolting and/or welding on site. Applications for large size bag houses generally include big centralized de-dusting/dust collection systems, Fume & dust cleaning systems for furnaces, boilers, kilns, raw material stock house, cast house, foundry and many more.

Bag Houses handling larger air/fume/gas volumes generally supplied with following features:

- ✶ Filter bags access & maintenance from clean air plenum top or through walk-in plenum

- ✶ Snap band clamp less filter bags, easy to replace

- ✶ Clean air plenum mock assembled at shop together with blow tubes, headers & pulse valves (to avoid mismatch misalignment at site) & then dispatched in dismantled condition

- ✶ Manufactured & supplied in pre-fabricated modules/panels

- ✶ Module/panels are sized considering shipping/transport limitations

- ✶ Modules/panels are site assembled by welding & or bolting

- ✶ Tube sheet holes are laser cut for accuracy of hole dia, pitch, spacing leading to effective & efficient bag cleaning & to ensure leak tight bag fixing

- ✶ Robust design venturi & cage assembly

- ✶ Material of construction as recommended for the process/application

- ✶ Application oriented & customized dirty gas inlet arrangement

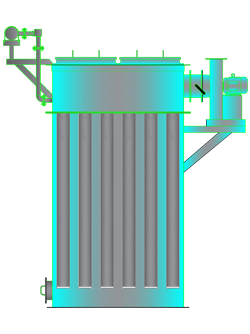

Medium size square or rectangular construction bag filters suitable for handling volumes upto 50,000 m3/Hr are manufactured & supplied in fully assembled condition except the internals. Applications for these bag filters generally include medium size centralized de-dusting/dust collection systems for material handling equipments, product collectors for chemical/mineral dryers, food products, foundries, fine chemical manufacturing plants, spray dryers, pesticide, insecticide, weedicide manufacturing plants and in many more industries.

Bag Filters handling lesser air/fume/gas volumes generally supplied with following features:

- ✶ Plenum, Tube sheet, housing & hopper in fully assembled condition

- ✶ Clamped plenum top access doors

- ✶ Venturi & cage assemblies, filter bags supplied loose for site assembly

- ✶ Compressed air header, pulse valves, sequential timer & other instruments & accessories supplied loose for site assembly

- ✶ Shop painting externally and/or internally

- ✶ Tube sheet holes are laser cut for accuracy of hole dia, pitch, spacing leading to effective & efficient bag cleaning & to ensure leak tight bag fixing

- ✶ Robust design venturi & cage assembly

- ✶ Material of construction as recommended for the process/application

- ✶ Application oriented & customized dirty gas inlet arrangement

Flange mounted Bin Vent bag filters are installed on top of silos, hoppers and bins for venting dispersed air due to material filling or separating dust from air in pneumatic conveying system.

Flange mounted bin vent Bag Filters generally supplied with following features:

- ✶ Plenum, Tube sheet, housing with bottom mounting flange in fully assembled condition lamped plenum top access doors

- ✶ Venturi & cage assemblies, filter bags supplied loose for site assembly

- ✶ Compressed air header, pulse valves, sequential timer & other instruments & accessories supplied loose for site assembly

- ✶ Shop painting externally and/or internally

- ✶ Tube sheet holes are laser cut for accuracy of hole dia, pitch, spacing leading to effective & efficient bag cleaning & to ensure leak tight bag fixing

- ✶ Robust design venturi & cage assembly

- ✶ Bag capture wire cage/grid

- ✶ Material of construction as recommended for the process/application

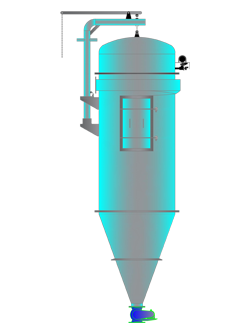

Cylindrical bag filters designed for high vacuum or high pressure applications & to handle higher filtration rates. Applications for these bag filters generally include unit dust collection or product collection systems for grinding mills, spray dryers, etc, food products, explosive fine dust handling eg coal, sugar, sulphur, etc, collecting fluffy, light weight dust particles and many more.

Cylindrical Bag Filters generally supplied with following features:

- ✶ Plenum, Tube sheet, housing & hopper in fully assembled condition

- ✶ Clamped plenum top access doors for low pressure / vacuum design

- ✶ Dished end with davit arrangement for high pressure / vacuum design

- ✶ Tangential entry at housing bottom/hopper top

- ✶ Involute entry at housing top

- ✶ Venturi & cage assemblies, filter bags supplied loose for site assembly

- ✶ Compressed air header, pulse valves, sequential timer & other instruments & accessories supplied loose for site assembly

- ✶ Shop painting externally and/or internally

- ✶ Tube sheet holes are laser cut for accuracy of hole dia, pitch, spacing leading to effective & efficient bag cleaning & to ensure leak tight bag fixing

- ✶ Robust design venturi & cage assembly

- ✶ Material of construction as recommended for the process/application

Bag or drum unloading / charging units are used to empty small drums or bags of material in a dust free manner. Optionally these are integral with filter bags & exhaust blower OR the unit is connected to centralized de-dusting system. These units are generally custom designed to suit the operation at site.

Bag Dump stations generally supplied with following features:

- ✶ Extended bottom hopper with gratings

- ✶ Hinged door/s

- ✶ Dust extraction/vent arrangement

- ✶ Support frame for the unit (Optional)

- ✶ Plenum, Tube sheet, header, blow tubes in fully assembled condition (Optional)

- ✶ Pulse valves, sequential timer (optional)

- ✶ Shop painting externally and/or internally

- ✶ Material of construction as recommended for the process/application

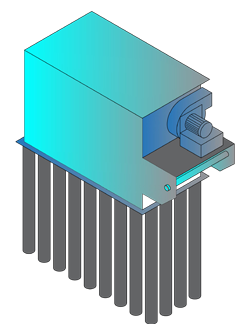

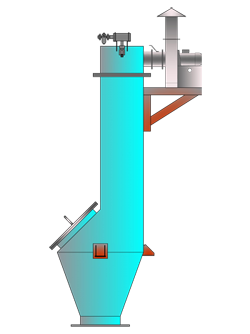

Insertable filters are installed where space limitations in the process. These are self-contained units integral to an existing enclosure, allowing dust to be dropped & retained at the point at which it is generated. These are easily mounted on material handling conveyors, material receiving hoppers, bins, fluidized silos, etc

Insertable vent Bag Filters generally supplied with following features:

- ✶ Plenum, Tube sheet, header, blow tubes in fully assembled condition

- ✶ Clamped plenum top access doors

- ✶ Venturi & cage assemblies, filter bags supplied loose for site assembly

- ✶ Pulse valves, sequential timer & other instruments & accessories supplied loose for site assembly

- ✶ Dust hopper & discharge equipment not required

- ✶ Shop painting externally and/or internally

- ✶ Tube sheet holes are laser cut for accuracy of hole dia, pitch, spacing leading to effective & efficient bag cleaning & to ensure leak tight bag fixing

- ✶ Robust design venturi & cage assembly

- ✶ Material of construction as recommended for the process/application