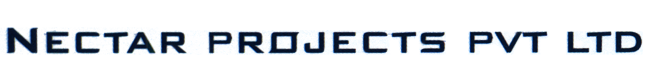

Low energy multi-vane scrubbers are designed for handling higher inlet dust loads, low pressure drop, less scrubbing liquid requirement at lesser pressure & scrubbing efficiency over 99% down to ~ 5 micron. Applications for multi-vane scrubbers includes, furnaces in iron & steel plants, kilns, scarfing, mineral & chemical grinding mills, dryers, de-dusting systems, boilers, etc.

Features : Low energy multi-vane scrubbers

- ✶ Tangential gas or air inlet.

- ✶ Multiple & circular scrubbing vanes.

- ✶ Scrubbing liquid pipe; can handle high solid concentration in recycle liquid

- ✶ Vane type mist eliminator

- ✶ Minimum maintenance since no moving parts

- ✶ Inspection / access doors

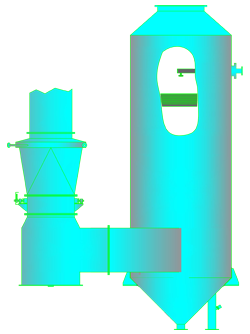

High energy venturi scrubbers are designed for effective removal of any noxious gases, particulates, odors, fumes, and dusts from the incoming gas. Sub-micron dust particles are also efficiently scrubbed using higher pressure drop across the venture throat creating high turbulence zone where maximum gas-liquid-dust particle contact and mixing takes place which results effective scrubbing. Scrubbing efficiency of over 99% is achieved down to sub-micron particle size. Used in industries viz iron & steel, non-ferrous, carbon black, mining, fertilizers, etc for applications like furnaces, kilns, scarfing, dryers, coolers, centralized de-dusting systems, boilers, etc.

Two stage venture scrubbers are used for Gas Cleaning Plants where dust outlet emission required below 5 mg/Nm3 e.g. Blast Furnaces where the cleaned gas is reused as fuel.

Pre-quencher is also provided before venturi for applications handling high inlet temperatures.

Features : High energy venturi scrubbers

- ✶ Manual adjustable throat

- ✶ Non-clogging flap type throat

- ✶ Scrubbing liquid pipe; can handle high solid concentration in recycle liquid

- ✶ No wet-dry inlet line build up

- ✶ Tangential inlet to cyclonic separator

- ✶ Minimum maintenance

- ✶ Inspection / access doors

Options

- ✶ Motorized or Pneumatically operated throat

- ✶ High pressure drop venrturi & throat upto 2000 mmWC

- ✶ Hard facing on venturi inner surface

- ✶ Hard facing on throat flaps

- ✶ Special alloy construction material for wear portion

- ✶ Radial inlet to cyclonic separator

- ✶ Vane type mist eliminator in cyclonic separator

- ✶ Chevron mist eliminator for larger size separators

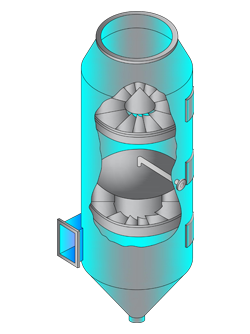

Medium energy integral fan scrubbers also named as centrifugal dynamic scrubbers are compact; designed for effective dust removal up to 99%+ efficiency down to 1-2 micron range in minimum space with low scrubbing water requirement. Rugged construction with minimum maintenance. The integral fan is thoroughly wet all the time with water film on the blades thus eliminating dust build up on fan impeller & its erosion due to abrasion. Used in industries viz iron & steel, non-ferrous, mining, pelletizing, sintering, pulp & paper, etc for applications like foundry shake-outs, oil mist & fume scrubbing, cupolas & other melting furnaces, sinter mixers, centralized / unit de-dusting / hygiene scrubbers, etc.

Features : Medium energy integral fan scrubbers or centrifugal dynamic scrubbers

- ✶ Compact design with integral fan

- ✶ Non-clogging, self cleaning fan

- ✶ Tangential inlet to cyclonic separator

- ✶ Efficient for dust as well as gaseous & mist cleaning

- ✶ Low scrubbing water requirement

- ✶ Capable for handling higher inlet dust loads

- ✶ Minimum maintenance

- ✶ Inspection / access doors

Options

- ✶ Multiple scrubbing stages to suit application

- ✶ Vane type mist eliminator

- ✶ Mesh type mist eliminator

- ✶ Chevron type mist eliminator

- ✶ Multi-rod deck type inlet venture

- ✶ Special alloy construction material for wear portion

- ✶ Radial inlet to cyclonic separator

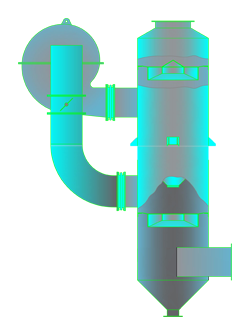

High efficiency mist eliminators are designed for virtually removing all type of mists from any gas stream. Also very effective to arrest larger dust particles without using conventional wet scrubbers. The mist & dust is efficiently collected by means of mechanical impingement at minimum pressure drop. Their applications are in petrochemical, steel & non-ferrous, paper, sugar, fertilizer industries in addition to remove scrubbing liquid droplets / mist from conventional scrubbing protecting down stream equipment such as suction fan.